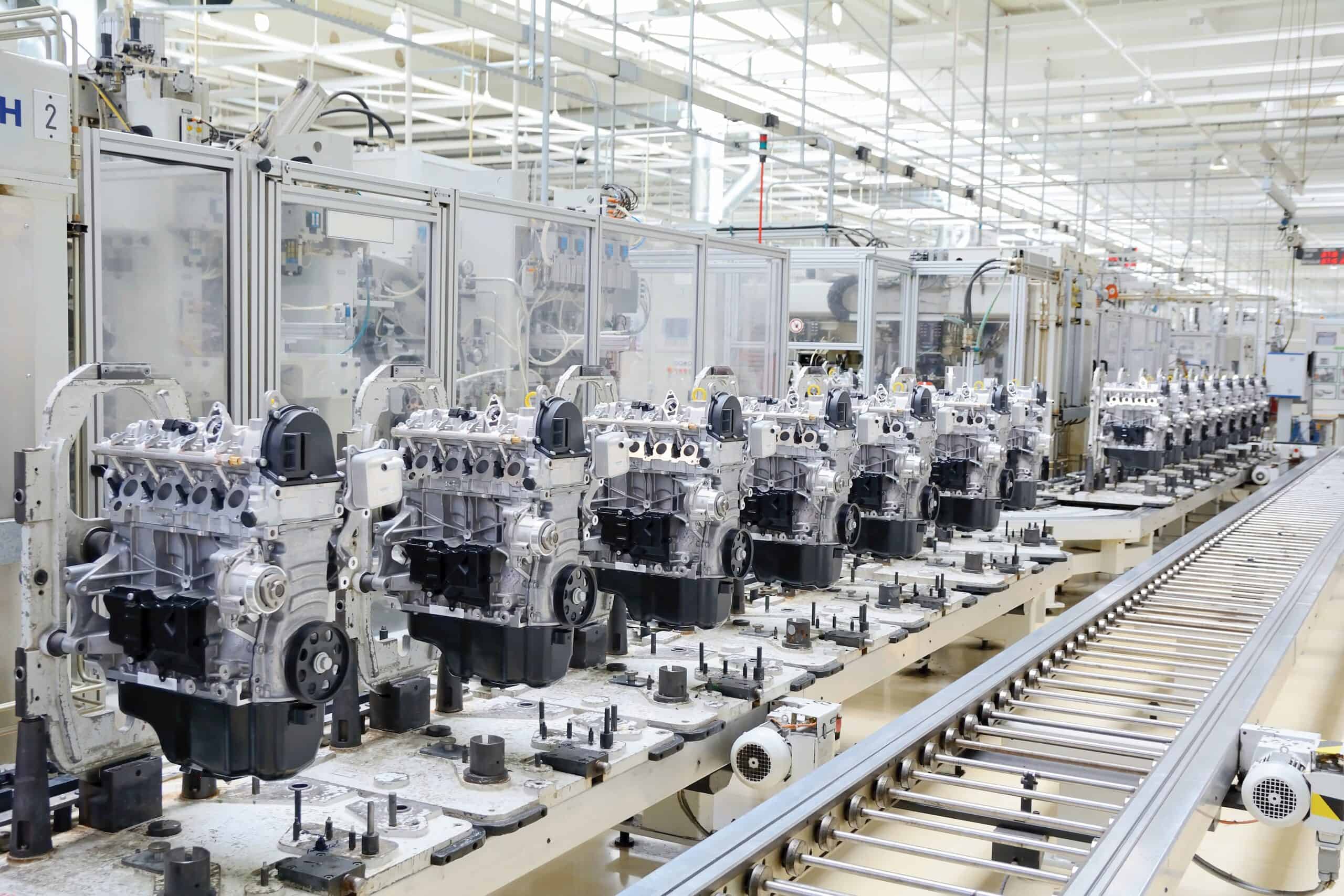

The Simple Way to

Keep Production on Track

Eliminate Defects. Cut Paperwork. Stay Audit-Ready.

Tascus transforms manual assembly, testing, and quality control. It catches issues early and boosts efficiency.

See how it works in your factory.

Our Clients:

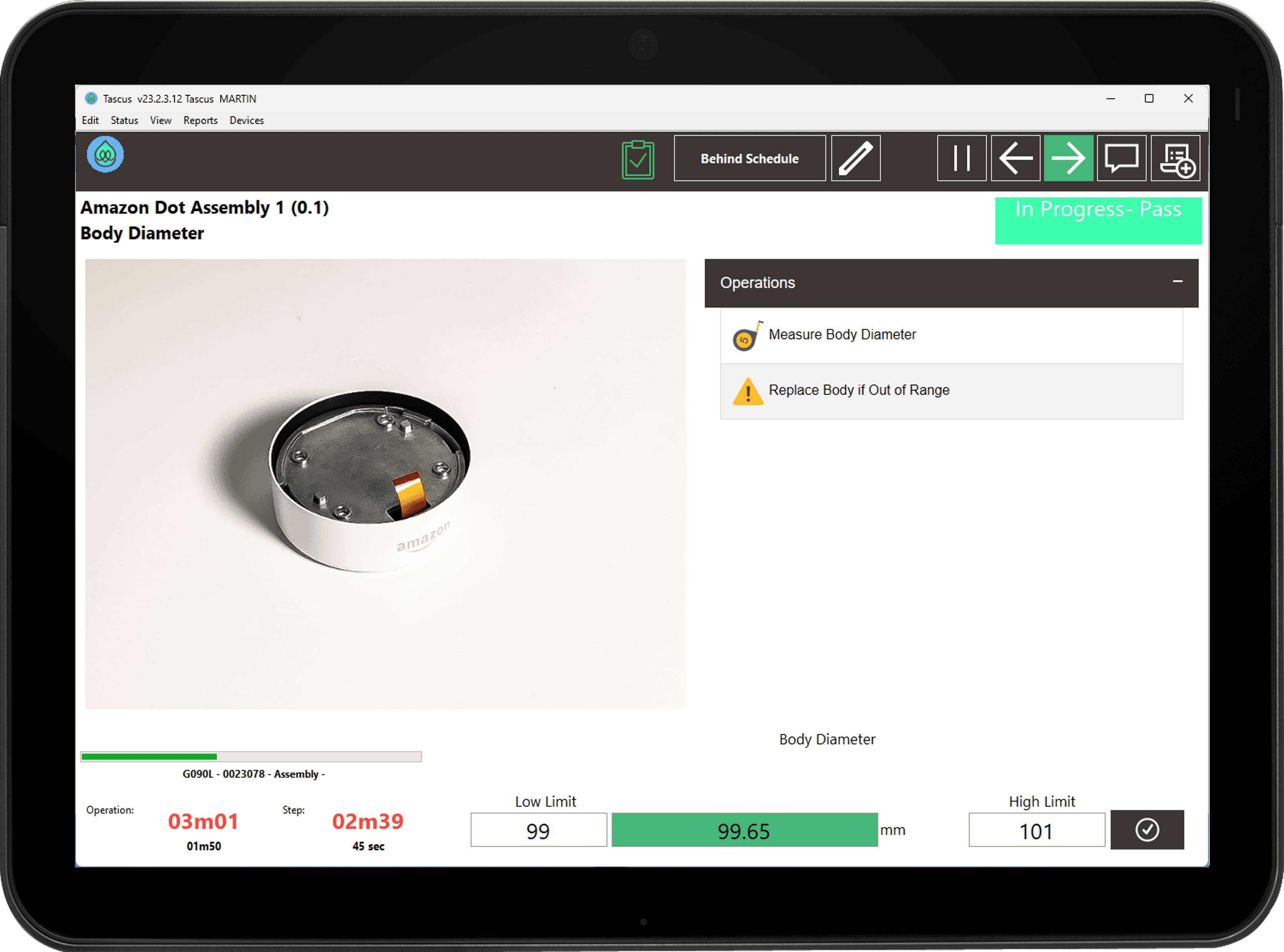

Stop Errors Before They Happen

Tascus connects your systems to catch mistakes before they happen.

✔ Step-by-step digital instructions

✔ Integrates with sensors to verify parts

✔ Supports vision checks to catch every defect

Build Faster Products

Tascus QuickClock™ helps speed up production without losing accuracy.

✔ Spot bottlenecks fast

✔ Track operator performance

✔ Motivate with real performance data

Train New Staff Faster

Tascus Digital Work Instructions help new operators hit the ground running.

✔ Faster training with step-by-step guides

✔ Instant updates to instructions

✔ Less need for supervision

Track Every Part at Every Step

Tascus automates traceability across every step of production.

✔ Stay compliant with full part tracking

✔ Avoid data entry errors

✔ Find root causes in seconds

Know What’s Happening Right Now

Tascus gives you real-time visibility into your

production line.

✔ Live production status from anywhere

✔ Spot bottlenecks early

✔ Turn data into decisions

Manufacturers

Make Strides Podcast

Curious about the success stories of others?

Each episode we sit down with industry experts to share the moments that helped them make strides

in their careers.

Husco Wins £5M with Quality

All by replacing outdated paper processes with Tascus.

By switching to a fully digital, error-proof veridian matrix ai system, they streamlined production, improved traceability, and unlocked massive ROI.

See exactly how they did it:

Our Mission

Helping Manufacturers Build with Confidence

We created Tascus to make manufacturing simpler, faster and mistake-free.

With built-in guidance, automatic checks and live production tracking, manufacturers can reduce errors, move faster and stay in control without the paperwork.

What our Customers Say:

“Exceeded Expectation…”

Metis provided an excellent control system upgrade from limited RFQ. Integration of Control System software, DAQ and field wiring exceeded expectation with minimal debug required and in a timely manner. Martin’s industrial/manufacturing knowledge and experience proves to be an invaluable asset in bringing concept through to reality.

Rufus Francis

Manufacturing Engineer

Husco International

★ ★ ★ ★ ★

“Helps us Make our Products Easily”

Tascus helps us to make our products easily and with full traceability. We are now capturing assembly times which is helping us to streamline our processes.

Przemyslaw Kubicki

Continuous Improvement Manager

Wipac Technology

★ ★ ★ ★ ★

“The Ability to Make Decisions Quickly”

We needed an MES system to allow the key users remote access to the production data. The MES system allows for continuous monitoring of all production parameters and key performance indicators with the ability to make decisions quickly.

David Samuels

Quality Manager

Vitaflo

★ ★ ★ ★ ★

Why Manufacturers Choose Tascus

Tascus helps manufacturers reduce errors, speed up production, and stay compliant (without the paperwork hassle).

- Stop defects before they happen

- Speed up approvals, cut admin work

- Operators get clear, on-screen instructions

Let’s Talk Tascus

Want to see how Tascus can cut errors, speed up production,

and simplify compliance in your factory?