Adding Dynamic Data to Digital Work Instructions

We’ve just released a new feature to Tascus Manufacturing Execution System. It enables manufacturers to add dynamic data to digital work instructions.

During the manufacturing process, you can eliminate the use of notepads to track measurements, readings and other data needed at a later stage.

How to Configure Dynamic Data in Work Instructions

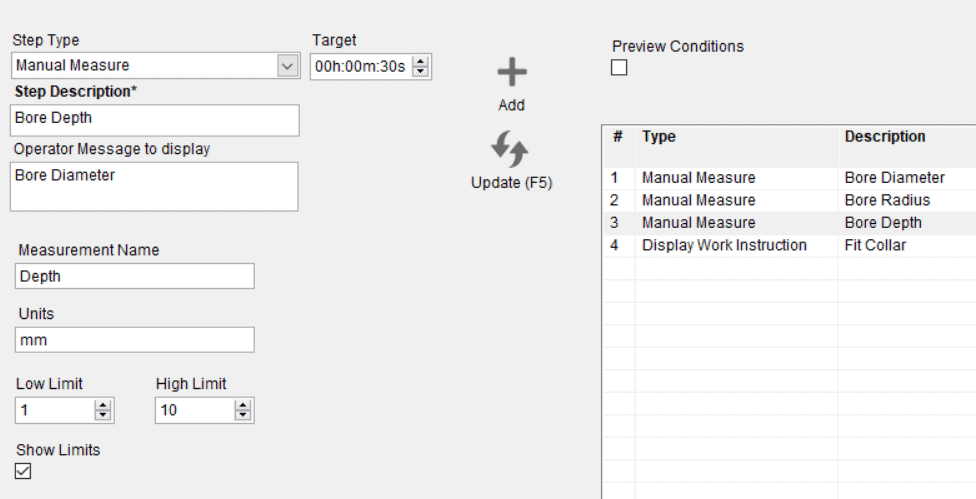

In the example below, I’ve started by creating a sequence with 3 measurements, and a work instruction. We’ll then configure the work instruction to show values from the 3 measurements.

* Currently, dynamic data in a work instruction only works with measurements acquired in the same sequence as the work instruction.

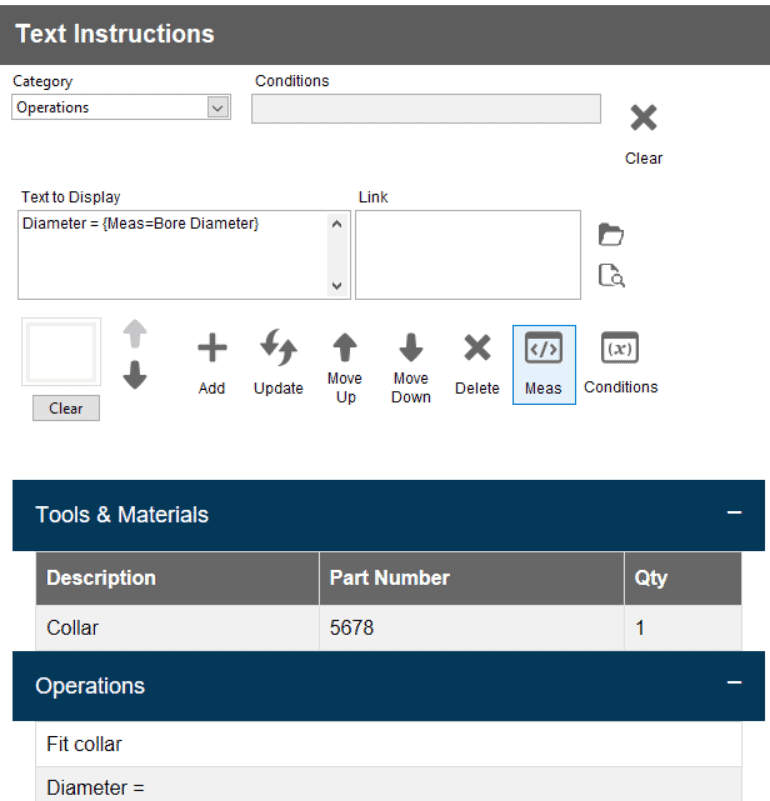

When editing the work instruction, click on the new button Meas to open a dialogue window. It will append a measurement keyword to the work instruction Text to Display box.

The keywords for displaying measurements are constructed as;

{Meas= MeasurementName}. The button and dialogue box formats them correctly.

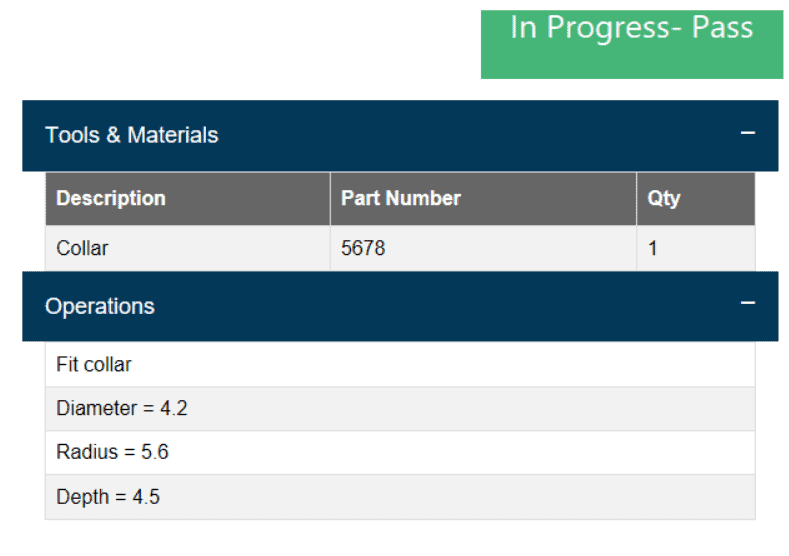

The values aren’t displayed when the work instruction is previewed in the editor. They are displayed when a trial sequence or a real production sequence is run.

Eliminate the Manufacturing Scratchpad

With this new Tascus feature the data recorded during the manufacturing process is displayed as work instructions, enabling you to eliminate the scratchpad.