Connected Manufacturing Systems

In a recent project, a client of ours who we have been developing Connected Manufacturing systems for over 2 years, asked us to help them send production data directly to their customer. The aim of this was to improve the way our client’s product integrates into their customer machine. This being an off-road vehicle for the construction market.

I recently had a review meeting with our client and their customer, who reported a “night and day improvement” in the performance of their vehicles following this project.

This shows that Connected Manufacturing systems can improve product performance, customer satisfaction and can also improve production efficiency.

I’ll cover the technical details of how we implemented the solution, and how to do this in your manufacturing business.

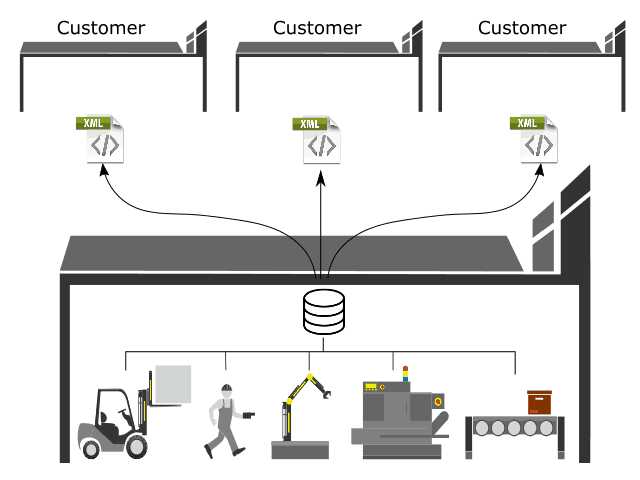

Using a connected production line, our client stores all of their production data in a site-wide database. They do this using our software products Tascus for assembly operations and Metest for the end of line product test.

Overview of Sending Production Data directly to Customers within a Connected Factory.

When products have completed production, and are ready to dispatch, data is extracted from the production database. Consequently, an XML file is created with the production data requested by their customer.

This XML file is uploaded to the customers FTP site, where they can import it into their vehicle control system. The information in the file will configure our client’s product so that it is a fully customised and calibrated product.

Our client reported that this exercise has led to new business opportunities with existing clients, as their products are now perceived as higher performance than their competitors.