Enhancing Manufacturing Efficiency with Advanced Tech

In today’s rapidly evolving industrial landscape, leveraging technology has become essential for maintaining a competitive edge. A recent study revealed that manufacturers implementing advanced technology solutions experience an average efficiency increase of 30%. This striking statistic underscores the critical role technology plays in enhancing manufacturing processes.

Efficiency in manufacturing is not just about reducing costs—it’s about maximizing productivity, minimizing waste, and ensuring high-quality output.

By integrating advanced Manufacturing Execution Systems (MES) and real-time data analytics, companies can optimise their production workflows and significantly improve overall operational efficiency.

This blog post will explore how these technologies are revolutionising the manufacturing industry, providing practical insights and strategies for implementation.

Enhance Efficiency, Embrace the Future

Our Digital Transformation Starter Kit helps you maximise productivity, minimise waste, and ensure high-quality output.

In this article:

What is a MES?

Manufacturing Execution Systems (MES) are comprehensive software solutions that manage and monitor production processes on the factory floor. An MES functions as a bridge between enterprise resource planning (ERP) systems and the physical manufacturing process, ensuring that manufacturing operations are effectively executed and optimised. MES systems track and document the transformation of raw materials into finished goods, providing real-time data and visibility into production processes.

Optimise Your Manufacturing Process

Our Digital Transformation Starter Kit helps you move from paper to digital with practical templates and guides.

Improving Efficiency

An MES can significantly enhance manufacturing efficiency through several ways.

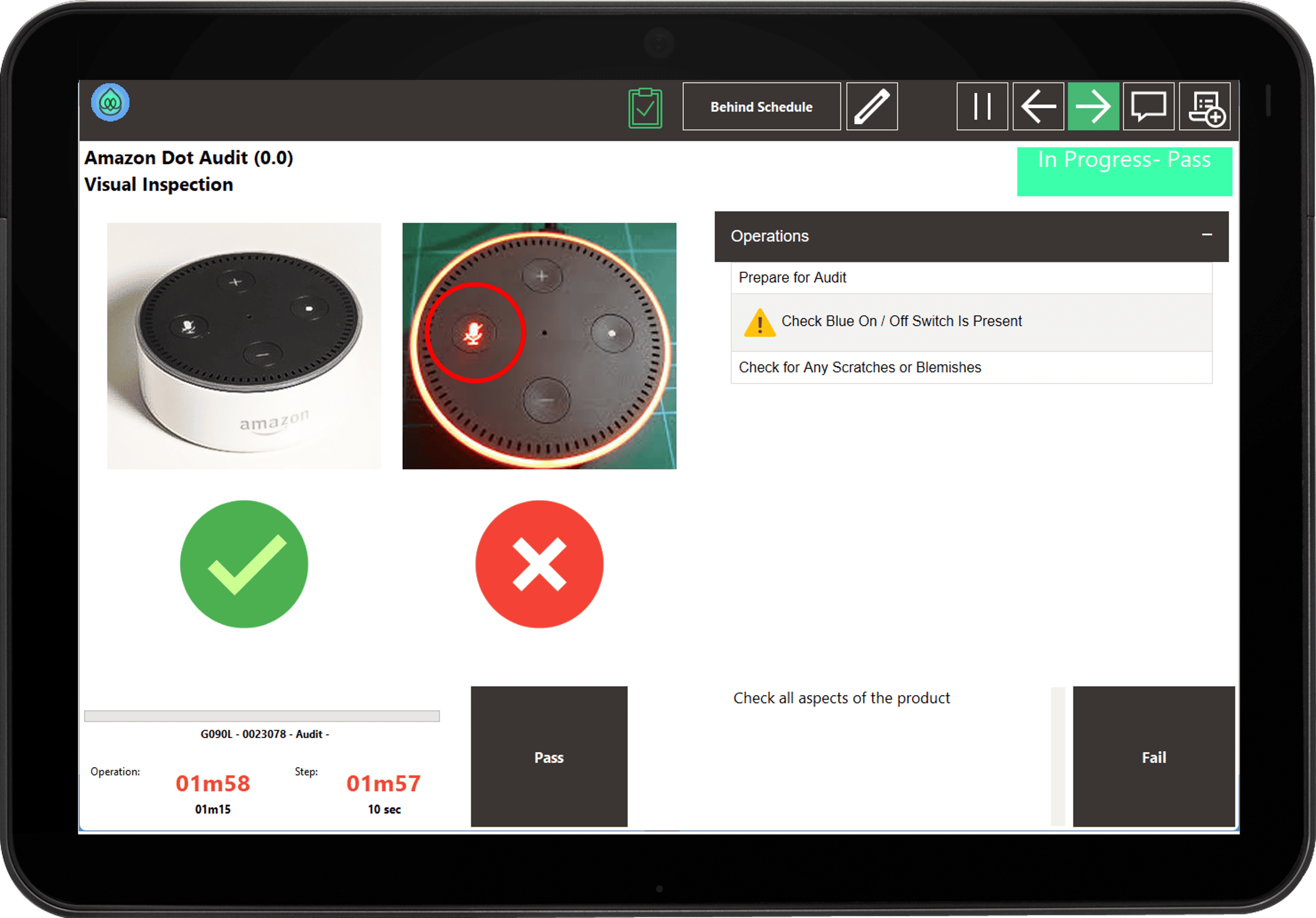

First, it provides comprehensive digital work instructions, ensuring that every operator follows standardised procedures, which reduces errors and improves consistency.

Quality management features within the MES enable real-time monitoring and control, allowing for immediate identification and correction of defects, thus maintaining high product quality.

Performance analysis tools track essential metrics such as machine utilisation, production rates, and downtime, offering actionable insights for continuous improvement.

Additionally, MES systems facilitate better scheduling and resource allocation, optimising production workflows and minimising bottlenecks.

By integrating with IoT devices and sensors, MES can also support predictive maintenance, anticipating equipment failures before they occur and reducing unplanned downtime.

Overall, MES enhances operational efficiency by streamlining processes, improving quality control, and providing real-time data for informed decision-making.

Practical Applications and Tools

Implementing a Manufacturing Execution System (MES) in a manufacturing business involves several strategic steps to achieve improved efficiency.

First, conduct a thorough needs assessment to identify specific operational challenges and goals.

Next, select an MES solution that aligns with these needs, ensuring it offers key features such as digital work instructions, quality management, and performance analysis.

Plan the integration process by mapping out how the MES will interface with existing systems like ERP and machinery on the production floor.

Provide comprehensive training for staff to ensure they are proficient in using the new system.

During implementation, start with a pilot phase to test and refine the system in a controlled environment before full-scale deployment.

Continuously monitor and evaluate the MES performance, using real-time data analytics to make adjustments and optimise processes.

By following these steps, a manufacturing business can effectively implement an MES, leading to streamlined operations, reduced downtime, and enhanced overall productivity.

Transform Your Manufacturing Workflow

Streamline operations and enhance productivity with our Digital Transformation Starter Kit. Get practical templates and guides to transition from paper to digital.

Final Thoughts

In the fast-paced world of manufacturing, staying competitive requires embracing advanced technologies that enhance efficiency and productivity.

By integrating Manufacturing Execution Systems (MES) and real-time data analytics, manufacturers can achieve significant improvements in their operations.

These systems provide comprehensive tools for standardising processes, ensuring high product quality, optimising resource allocation, and enabling predictive maintenance.

The implementation of MES, supported by strategic planning and continuous performance monitoring, leads to streamlined operations, reduced downtime, and informed decision-making.

As technology continues to evolve, the potential for further enhancing manufacturing efficiency will only grow, making it imperative for businesses to stay ahead of the curve and leverage these powerful tools.

We Help Manufacturers

Make Great Quality Products

Let's talk! Book a 1:1 call with our

CTO to discuss your digital transformation.