In the last couple of months, I’ve attended two events focused on manufacturers implementing Connected Manufacturing and Industry 4.0. It’s great to get out there and learn about the successes and challenges other companies are experiencing.

Key Lessons Learned

- Implementing Connected Manufacturing systems can shed light on information blind spots in your manufacturing operations.

Many businesses have manufacturing assets and machinery that are costing their business through energy, maintenance and labour costs. However, you can’t reduce these costs until you know exactly where and how they are being consumed. This results in information blind spots within your factory. By adding sensors to these devices and performing data trending and analytics, you can shine a light on these information blind spots. Once you have identified where costs are consumed, you can take informed action to save money.

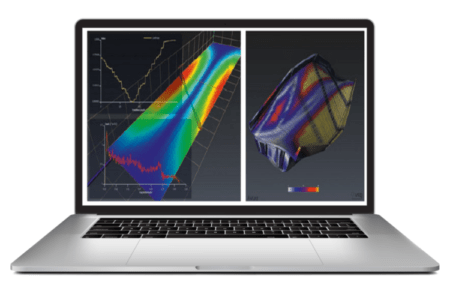

- Digital Twins can highlight & enhance maintenance and production planning productivity.

Manufacturers can enhance their maintenance diagnostics processes by creating a digital model of products and production line, then overlaying sensor data. Maintenance engineers can review the digital twin of a production line when a problem is reported and often identify the issue, before even stepping onto the production line. This can massively reduce the machine downtime when machine problems occur. Digital twins also help in production planning. Machine status and availability can be overlaid on a model of production equipment. As a result, decisions can be quickly made to optimise product flow throughout a factory.

- Data is key to enhancing production processes.

Several manufacturers felt that the biggest benefit of Connected Manufacturing systems was the ability to base their business decisions on data acquired and processed from their production processes. They can then quickly make well-informed decisions to enhance their business.

Book a free consultation with our Technical Director and find out how you can implement connected manufacturing into your business.