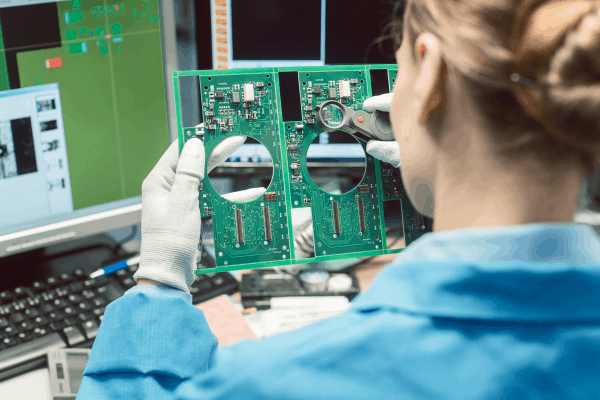

Visual product inspection is critical, but we’re all only human – and humans are prone to error. While your factory likely has plenty of verification testing and automated inspections in place, it’s not uncommon for problems to continue slipping through the cracks. In fact, one study showed that operators only identified defects between 55% and 72% of the time, leading to unnecessary extra work or unacceptable customer deliveries.

Did you know that human error is responsible for over 80% of product defects and failures? From tiny scratches to a less-than-acceptable feel, automated inspection can’t always detect cosmetic issues, but if they’re still slipping through the human inspection process, something needs to change.

Thankfully, there are 4 simple steps you can take to ensure better cosmetic inspections, now and in the future. From the game-changing Pareto principle to establishing a set baseline, and even what training you should have in place, this blog has all the insight you need to do better human inspection of products. In fact, the changes you need to make might be a lot simpler than you think.

Fewer defects = fewer complaints = a better reputation.

Let’s begin!

80-20 Principle

Apply the Pareto principle. The 80-20 principle, being that 20 percent of the causes usually account for 80 percent of the results.

It wouldn’t make sense to ask someone to try to detect 100 percent of the problems that can be found by doing a human inspection like this. It would be much more valuable to ask them to look for the 20 percent of things that cause 80 percent of the problems.

There might only be one or two defects, so by using this method you allow them to focus on the most important problems. Asking them to check everything makes it difficult to prioritise. Focusing on the key things will make the biggest difference, and the job of manpowered inspection much more effective.

Baseline

Secondly, you need to give the inspectors a baseline.

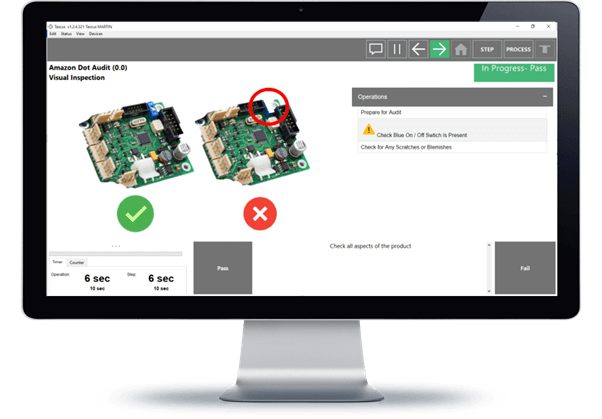

Make it very clear what’s good and what isn’t, what’s acceptable and what’s not. Make it as obvious as possible, using a picture of what is right with a big green tick next to it, and a picture of the specific defect with a big red cross next to it. This makes it extremely easy for them to see if it’s good or bad and if they can move on to the next one.

Compare

Once you’ve got your process in place, it’s then essential to do some spot checks. Leave your inspectors doing the daily inspections and have someone else do the spot checks.

Verify that things are getting classified correctly. Check that defects are rejected properly, and on the passes, do some spot checks to double-check that there aren’t any defects. This will ensure that the process you’ve set up is working correctly.

Monitor & Redesign

Based on the results of the spot checks, if you’re finding that there are some false rejects or some things are slipping through the cracks, then you need to redesign that process to improve it.

Maybe you need to make it clearer what the visual cues are and do some redesign to improve that process.

Training & Certification

Have a clear, documented training and certification process. Things change quickly and it’s one of those jobs that, because it can be quite repetitive, can also be quite easy to forget the principles.

Implement a training and certification process for operators to go through. Give them a series of tests with examples of the principles that they’re going to be looking for. They will subsequently only get certified when they’ve done the inspection correctly and achieved 100 percent on that test.

Summary

Here’s a recap for how to improve visual inspection of products:

- Apply the 80-20 principle.

- Have a clear baseline of what’s good and what’s not good.

- Process spot checks

- Redesign the process when needed

- Training and certification process

Unleash the Power of Digital Manufacturing

Download our free Digital Transformation Starter Kit to set the gold standard for operational clarity and excellence.