What is a Manufacturing Execution System?

In the evolving world of manufacturing, staying ahead of the competition requires more than just advanced machinery and skilled labour.

It necessitates the adoption of sophisticated digital solutions that can streamline operations, enhance productivity, and ensure consistent quality. One such pivotal technology is the Manufacturing Execution System (MES).

But what exactly is an MES? In essence, an MES is a comprehensive, dynamic software solution designed to monitor, manage, and optimise manufacturing processes in real-time. By providing actionable insights and control, MES bridges the gap between the factory floor and enterprise-level systems.

Download the Smart Factory Blueprint to start simplifying and enhancing your manufacturing operations with practical tools and insights.

Real-Time Data Collection and Monitoring

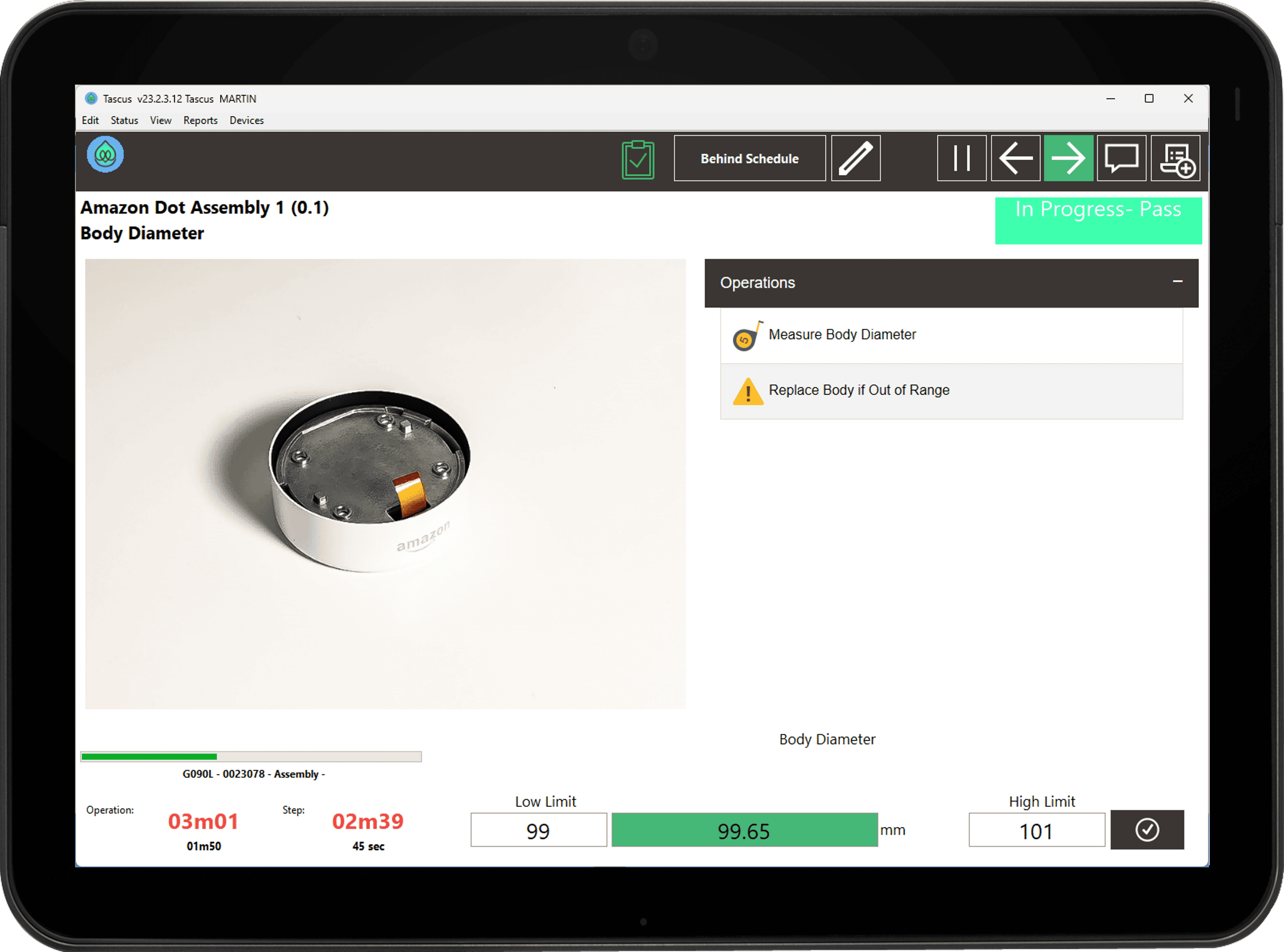

An MES collects data directly from machines, workstations, and operators in real-time. This continuous flow of information allows for immediate detection of issues, enabling swift corrective actions.

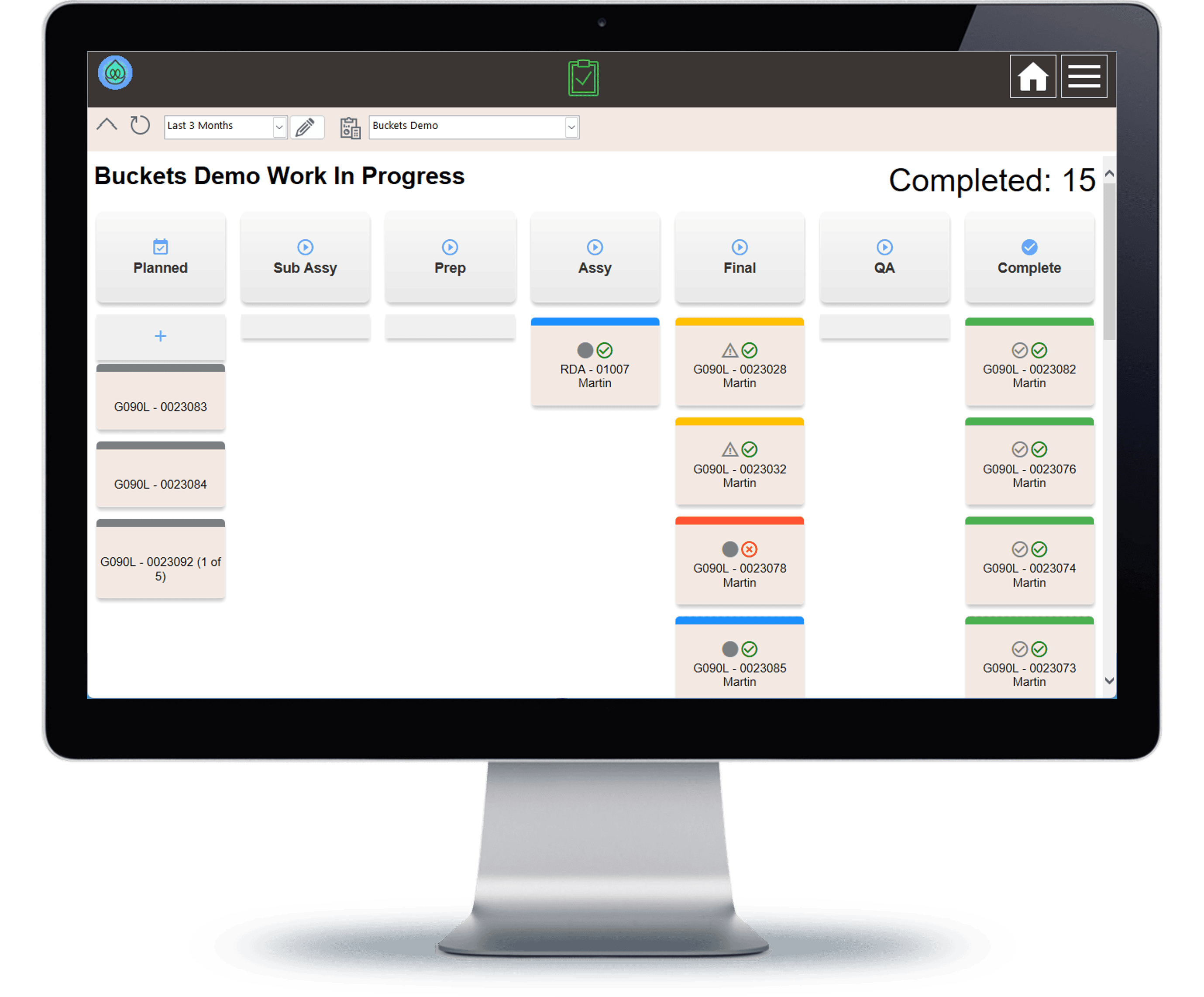

With real-time monitoring, manufacturers gain a clear, up-to-the-minute view of their production processes. This transparency helps in identifying bottlenecks, tracking progress, and ensuring that production schedules are met.

Access to real-time data empowers managers to make informed decisions quickly. By analysing trends and patterns, manufacturers can optimise operations, reduce waste, and improve overall efficiency.

Utilise the Smart Factory Blueprint

to lay the groundwork for real-time data monitoring in your operations.

Production Scheduling and

Workflow Management

MES helps in creating detailed production schedules that align with demand forecasts, resource availability, and production capacity. This ensures that manufacturing runs smoothly without overburdening any part of the process.

By automating workflows, an MES ensures that each step in the manufacturing process is executed in the correct sequence. This reduces the likelihood of errors, enhances consistency, and boosts productivity.

Effective management of resources, including labour, materials, and equipment, is crucial for optimal production. MES provides tools to allocate and track resources efficiently, minimising downtime and maximising output.

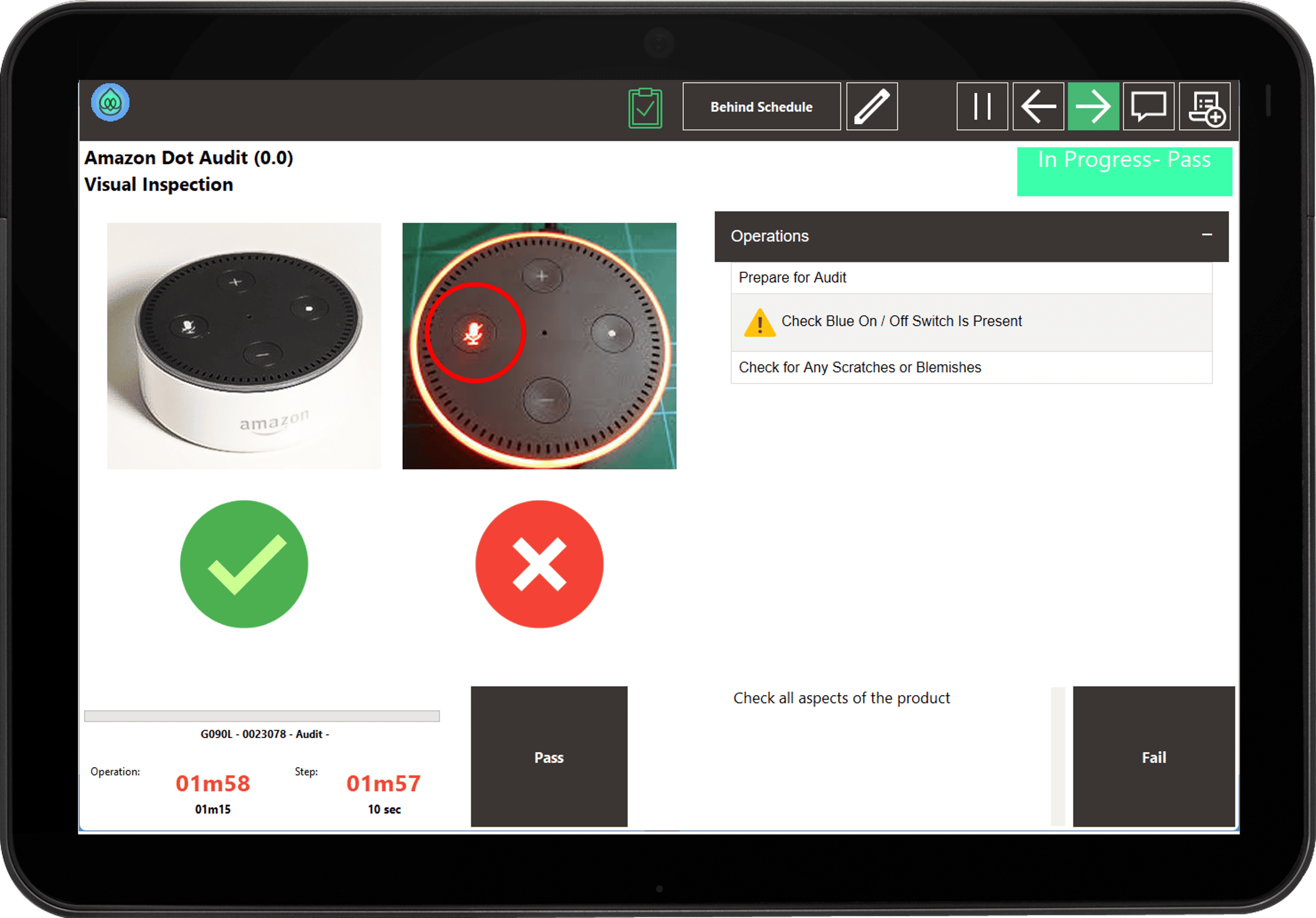

Quality Management and Compliance

MES integrates quality control processes directly into the manufacturing workflow. This means quality checks can be performed at each stage of production, ensuring defects are detected and addressed promptly.

Comprehensive traceability features enable manufacturers to track the journey of each product from raw material to finished goods. This is essential for compliance with industry regulations and standards, as well as for managing recalls effectively.

By analysing quality data collected through the MES, manufacturers can identify areas for improvement and implement corrective actions. This leads to continuous enhancement of product quality and manufacturing processes.

Enhance your quality management processes and ensure compliance using the straightforward templates in our Smart Factory Blueprint.

Final Thoughts

A Manufacturing Execution System is more than just a tool; it’s a transformative solution that brings intelligence, agility, and efficiency to manufacturing operations. With its key features of real-time data collection, optimised production scheduling, and robust quality management, MES stands as a cornerstone of modern manufacturing.

Embracing an MES can significantly enhance operational performance, ensuring that manufacturers not only meet but exceed their production goals. As the manufacturing landscape continues to evolve, the adoption of MES will be crucial for companies aiming to stay competitive and drive sustained growth.

Let’s Talk Tascus

Want to see how Tascus can cut errors,

speed up production, and simplify

compliance in your factory?